From Earth to Mars and Beyond

Raytheon Intelligence & Space offers end-to-end space solutions

They make it possible to warn people about extreme weather. They help spot the first signs of wildfires. They keep soldiers connected on the modern battlefield.

The Earth-observation instruments and next-generation software systems developed by Raytheon Intelligence & Space, a Raytheon Technologies business, are providing critical information and managing enormous amounts of data gathered by the business's satellites and sensors in orbit.

Here are several ways those end-to-end technologies are enabling better decision-making through greater understanding of the Earth and of the universe.

Weather prediction for any condition

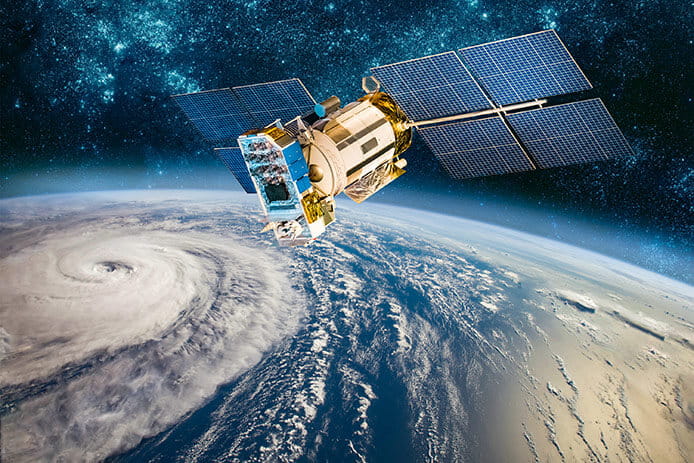

Today’s weather forecasts can help people decide whether to grab an umbrella on the way out or get ready for a big storm. A new class of small satellites in development at Raytheon Intelligence & Space could provide even better data to inform those decisions.

The new Earth-observing small satellites have enhanced capabilities including higher fidelity weather imaging, cloud characterization, ocean surface winds, soil moisture content, tropical cyclone intensity and other key data sets needed to improve weather observations and forecasting.

“If a tropical cyclone started to develop at night, we would still be able to see it with these enhanced capabilities,” said Shawn Cochran, senior manager for Space & C2 Systems at Raytheon Intelligence & Space. “That improves forecast track error, allowing us to better understand of the lifecycle of hurricanes and tropical storms. This adds days of early warning instead of hours that could save lives and property.”

The new program draws from the success of the Joint Polar Satellite System Common Ground System, which uses cloud-enabled resources for mission management, command and control, data processing and data delivery of the satellites.

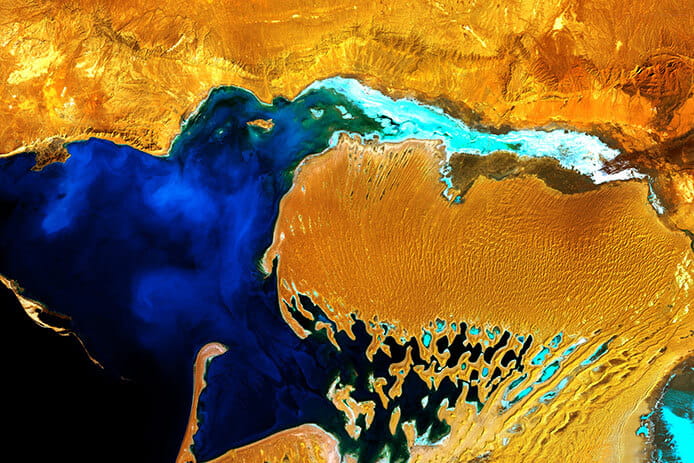

Landsat 7 captured the Dardzha Peninsula in western Turkmenistan, among the shallow coastal terraces of the Caspian Sea. Strong winds create huge sand dunes near the water, some of which are partly submerged. Further inland, the dunes transition to low sand plains. (Credit: USGS)

Looking beyond Landsat 7

The land-observing satellite was supposed to work for five years. Now, more than 20 years later, Landsat 7 is still going strong.

In April 2021, the satellite marked its 22nd year of serving as a set of eyes on our home planet, documenting Earth’s splendors such as the expansion of cities and calamities like volcanic eruptions and historic wildfires. As the satellite notches another year, engineers from Raytheon Intelligence & Space are developing new technologies like a full-spectrum calibration system that could contribute to future generations of Landsat systems.

“Our Earth-observing capabilities provide actionable and timely observations – as demonstrated by our successes on Landsat 1-7 satellites,” said Paul Meyer, vice president for Space & C2 Systems for Raytheon Intelligence & Space, a Raytheon Technologies business. “The operating life of systems like Landsat 7 is one of our crowning achievements, with designs lasting 2.5 times longer than their design life on average.”

As NASA and USGS prepare to launch Landsat 9 in fall 2021 and the next-generation imaging satellite, Landsat NeXt, in the late 2020s, RI&S researchers are pioneering new, advanced technologies that could lend to a more sophisticated Landsat system that would continue its legacy of delivering data continuity.

Building smaller can sometimes compromise capability – but it doesn’t have to. RI&S engineers are developing a prototype imager called the Advanced Technology Land Imaging Spectroradiometer, or ATLIS, that can reduce size, weight, power and cost requirements while delivering even better data.

Digital engineering is enabling engineers at Raytheon Intelligence & Space to deliver products faster and more efficiently. Using modeling and simulation technologies, digital engineering saves time and money by exposing potential problems early.

Delivering with digital engineering

In the past, a complex military program with many requirements could take years to deliver. But the team working on a U.S. Space Force data analysis tool called Future Operationally Resilient Ground Evolution, or FORGE, didn’t have that kind of time. Nowhere near it, actually.

“On a program with a similar set of requirements, this process would’ve taken over two years to complete. We did it in two months,” said Karen Casey, a Raytheon Intelligence & Space engineering fellow. “Together with our customer, we did it differently.”

The team’s use of digital engineering is just one example of how engineers at Raytheon Intelligence & Space and across Raytheon Technologies are using techniques like modeling and simulation to provide customers what they need quickly, inexpensively and in a way that is easy to upgrade. Core to the digital engineering approach is the concept of failing fast: recognizing shortcomings early, and quickly pivoting to alternatives.

“We had several fails with tooling, processes, and training, and we accepted that as OK. Instead, we embraced the problem, and found a better way and moved forward,” said Casey.

The goal of the FORGE Mission Data Processing Application Framework is to make it easy for analysts to process and understand information from nearly any source. It can help them generate warnings, intelligence information for military personnel, and eventually it will be available for civilian first responders and researchers. The system’s main function is to enable the Space Force to develop and deploy applications for data analysis quickly.

Artificial intelligence and machine learning could help military commanders and operators by searching, combining and analyzing large amounts of data from every domain, then turning it into comprehensive, actionable intelligence.

How AI can alter multi-domain warfare

Military commanders often have very little time to make decisions – sometimes just seconds. And with threats like hypersonic missiles accelerating the pace of modern warfare, that window of time is shrinking.

Complicating things is the sheer volume of data flow. There are petabytes of intelligence information coming from sensors on land, at sea, in the air and in space, many using different formats.

The solution, according to experts at Raytheon Intelligence & Space, a Raytheon Technologies business, is clear: Artificial intelligence – specifically, teaming military commanders with intelligent systems to cull through data in seconds. This will be key to bringing the vision for the U.S. Department of Defense’s Joint All Domain Command and Control network, often called JADC2, to reality. That network will link military capabilities around the world and in every domain.

With artificial intelligence and machine learning, those systems can define, combine and provide the right information to the right people at the right time – giving them the best possible chance to make the best possible decision.

“Manually processing all that data would require armies of analysts, but with AI/ML, we can task systems to cull through the data and produce higher level information useful to operators,” said Jim Wright, RI&S technical director for Intelligence, Surveillance and Reconnaissance Systems.

An illustration of NASA’s Perseverance rover landing safely on Mars. Hundreds of critical events had to execute perfectly and exactly on time when the rover landed safely on Feb. 18, 2021. Raytheon Intelligence & Space developed technology that will help this NASA rover bring back samples from Mars to determine if life ever existed on the Red Planet. (Credit: NASA/JPL-Caltech)

Was there ever life on Mars?

NASA’s Perseverance rover exists for one reason: To find out if there was ever life on Mars.

And, as with just about any space mission, there’s a lot going on behind the scenes that will determine whether the mission succeeds. Perseverance’s job is to drill into the Martian surface to collect rock and soil samples. Those samples will be stored in sealed tubes and wait to be ferried back to Earth for analysis on a future mission.

“The whole mission hinges on the drill being able to do its job,” said David Appel, vice president of Defense & Civil Solutions at Raytheon Intelligence & Space, a Raytheon Technologies business. “The launch could be picture perfect. The touchdown ideal. But, if that drill doesn’t work, then the mission can’t succeed.”

One major factor in whether the drill works is whether it’s clean. To that end, RI&S engineers helped design two one-time deployment doors for the Adaptive Caching Assembly, or ACA. Behind those doors is the bit carousel, a subassembly that serves up whichever drill bit the rover’s robotic arm needs.

RI&S software engineers also supported the development of flight software to manage most of the scientific instruments onboard Perseverance.