Optics with pinpoint accuracy

Microns matter when Raytheon ELCAN designs optical systems

Being just barely a hair off is nowhere near good enough when it comes to precision optics.

An aberration – only 1/25th as broad as a human hair, caused during production – prevented the Hubble telescope from delivering razor-sharp imagery to NASA. Shuttle astronauts fixed the problem with a corrective optic in 1993.

“If you were to take a pair of glasses and shift them about an inch sideways either way, you’re going to get distortions,” said Tony Brinovec, program manager for space at Raytheon ELCAN, a Raytheon Technologies subsidiary. “You want your eye to look through the center of that lens. As you get into precision optics, you need to make sure the optical axis, which is like an imaginary line right through the middle of the system, is as perfect to the center as possible. So say we are looking through a telescope, which may have nine or 10 elements inside it, if some of those are not centered correctly, it’s not going to work properly.”

This level of precision is important in everything the company does. From optics for aircraft head-up displays to missile seekers and satellites, this alignment is critical for performance. The company doesn’t get a second chance to get it right.

“It’s not like we can look at the system and say, ‘Oh, there’s your 20 microns right there. That’s what moved,’” said Anthony De Aguiar, mechanical designer at Raytheon ELCAN. “No, we have to follow a pretty rigorous process of elimination of what we think could be moving, what could be out of alignment, and then troubleshoot from there. We call this troubleshooting process ‘chasing microns.’”

Raytheon ELCAN know that microns matter when it comes to their optical systems. That’s why the company invests in partnerships and in research and development to improve the precision of its optical systems so that it can help customers see better and farther, even from miles above the Earth.

The measure of performance

A common unit of measurement in optics is the micron – one millionth of a meter. Five microns is about 1/20th the thickness of a sheet of paper. In high precision optical systems, even a few tiny microns can make an enormous difference.

“The optics we’re designing need to see as far as they can,” said Kristy Dalzell, Raytheon ELCAN optical designer. “They need to resolve the smallest features so customers can identify and recognize them. So in terms of optics, we need precision alignment and precision mounting down to tolerances of about five microns or less.”

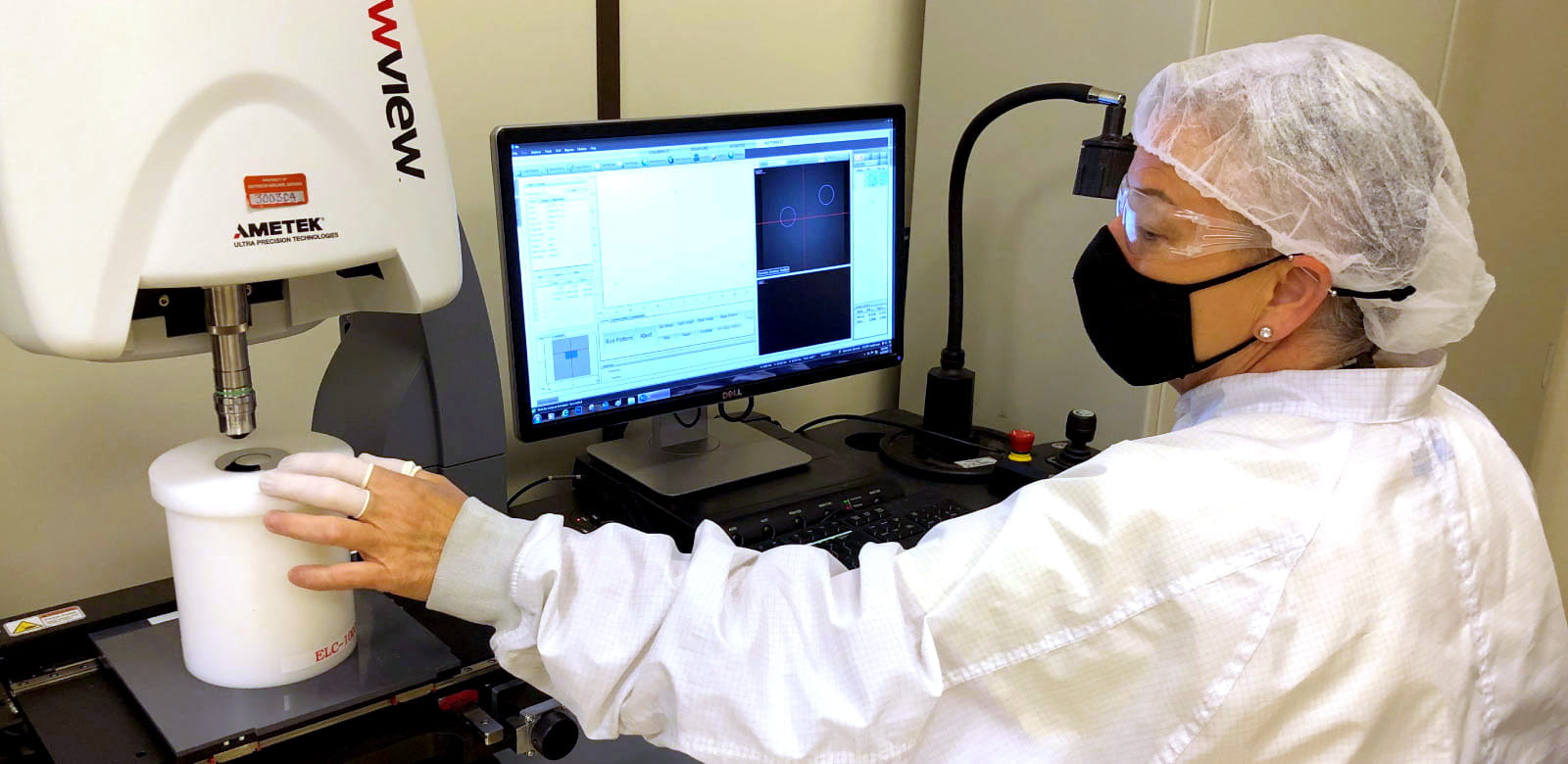

To achieve this level of precision, Raytheon ELCAN invests in machinery, technology and training to press the advantage. For example, Raytheon ELCAN developed a proprietary process called post-centering that leverages optical techniques to achieve high-precision tolerances; it capitalizes on costs, because it is cheaper to cut metal than glass. Optical elements are set into a mechanical mount, then the mount is precision cut rather than the optic, which delivers higher resolution at a lower cost.

“Our customers come to us because we do the hard stuff,” said David Taylor, a senior program manager for the precision optics mission area at Raytheon ELCAN. “We look at problems differently and deliver disruptive technology.”

All together better

Having all the capabilities under one roof, known as vertical integration, enables Raytheon ELCAN to design, manufacture and test full assemblies from concepts, specifications or build-to-print for critical sub-systems and assemblies.

Reg Jonas, Raytheon ELCAN optics technical manager, summarized this advantage and what it means to ELCAN’s customers.

“There’s a big advantage to having an integrated approach; we can precisely assemble glass and metal together, and test the performance” he said. “So we’ll add a few microns on, maybe take two or three microns off, to get the perfect fit. Those microns matter, and being able to have design, engineering and manufacturing working together in one place is critical.”